Most manufactured homes sit up off the ground with steps leading up to the doors. This often can make the home feel isolated from the outdoors. An elevated wood deck is a valuable addition to any manufactured home if it is built properly, but can be dangerous if it isn’t! How can you tell the difference?

Table of Contents

The Short Answer

Many mobile home decks are DIY weekend projects for homeowners. While the owner may mean well, there are simply millions of decks that are not built to local building codes.

Outdoor wooden decks are directly exposed to the elements and have a much shorter expectancy than the rest of the house. Because many decks are not built to professional standards and the materials are prone to rot, many mobile home outdoor decks are dangerous and in need of rebuilding or repair.

Mobile Home Wooden Decks Bring Added Value When Selling

When a manufactured home sits 18” to 30” or more above the ground, often nothing but a few steps are added at the front and rear exits for entry into the home. Often cement slabs may exist on each side of the home. Even with the best intentions, including nice outdoor furniture down on the slab, they rarely get used. Why?

When the outdoor weather is inviting, we often go in and out of the house to relax and enjoy the day. Trips into the kitchen to get snacks and a drink are just more inconvenient when you have to go back and forth, up and down some stairs. When a wooden deck is built at the height of the floor of the mobile home, it makes outdoor living more inviting and more usable. The door to the home can be left open and people are free to pass back and forth from inside the home to the deck.

In addition, a raised wooden deck is appealing aesthetically and makes any manufactured home look more substantial.

“Remodeling” magazine, in their research for the 2013 and 2014 year published in the annual “Cost vs. Value Report showed something interesting. They stated that a wooden deck addition returns on average 87.4% of the cost of the deck upon resale. The same cannot be said for many remodeling projects.

Mobile homes tend to be smaller overall than site-built homes. Adding a great wooden deck is an inexpensive way to extend the living space to a manufactured home.

Whether your mobile home already has a deck or you’re planning on putting one on, there are safety standards you should follow to get safe and enjoyable use of your deck for years to come. Maybe your deck just needs some repair and a little remodeling to make it the deck of your dreams! Maybe your deck is in poor shape and just needs to be removed to make room for a newly constructed deck.

When it comes to construction projects, we always try to follow our own advice. “Don’t cut corners when it comes to the quality of construction. You pay for it in the long run.”

A Wooden Deck Has A Fairly Short Life Expectancy

Wooden outdoor decks are directly exposed to sun, rain, and snow. No matter how well you may work at preserving the wood, it will degrade over time. The most likely places the degrading starts is in places where water puddles after rain.

Wood has a side that is cut across the grain. This end of the wood is more prone to allowing moisture in that will rot the wood. Wood expands and contracts significantly with moisture, heat, and cold. This natural movement causes the grain to open up and allows moisture into the lumber that will cause rot over time.

Pressure treated would certainly helps, but it will only prolong the inevitable. Wood that is directly exposed to the elements has a finite life span. You can slow it down with careful applications of sealer or paint, but warpage, shrinkage, and rot will happen over time. You can expect to get about 10 to 15 years of usage from your wooden deck if it is properly cared for. By then, you will probably have to perform structural repairs or replace the deck altogether.

Wooden Decks Are Often Built Incorrectly

Like most weekend warrior homeowner do-it-yourself kind of guy, sometimes I look at a project and think – I can do that! It is only after I get into some projects that I realize I’m in over my head.

At first glance, a wooden deck looks pretty simple to build. Well, it may seem that way, but to build a deck that is safe, structurally sound, is up to local building codes and built-to-last may be a bit more involved than the typical weekend-warrior expects.

Of the roughly 40 million decks built onto homes in the United States, it is estimated that half of them are non-compliant with local building codes. Many of these decks are downright dangerous and should probably be removed and or rebuilt.

Let’ take a look at the areas that need special attention to avoid the “dangerous deck” status!

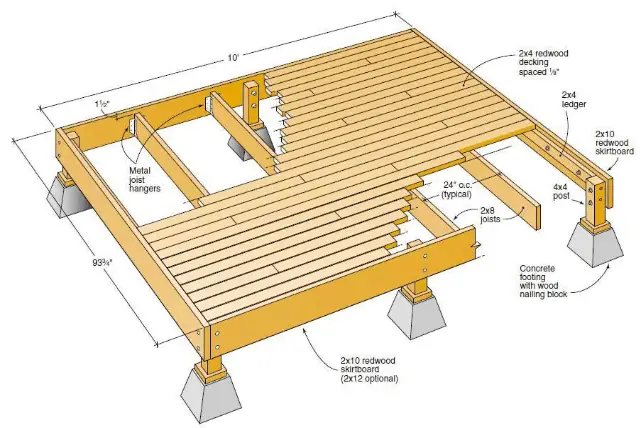

Number One Issue – A Load Path Directly To The Ground

As with any structure, a proper foundation is what holds everything up above the ground. With decks, you will find vertical support posts that a directly transfers the weight of the deck into the ground. Quite a few people feel that they can dig a hole, put the pole in and pour in some cement and call it a day.

This may certainly work for a time, but the post will rot if it comes into contact with the ground. Also, The cement footing is inadequate to properly support the weight.

Proper footings should comply with local codes, which most likely will require a hole of a certain width and depth to be filled with reinforced cement. The vertical deck support post will then be attached to this footing.

Mobile Homes Have a Special Issue

With a site-built home, the outer walls of the home direct the vertical weight of the wall directly onto the foundation and into the ground. Manufactured homes are not built this way. Each section of a mobile home uses two main steel I-Beams with floor joists mound perpendicular to the steel beams. The steel I-Beams are not located at the outer perimeter wall of the home. Instead, they are located more centrally under the home.

These steel beams sit on top of foundation piers that direct the weight of the home into the ground. So what has this all to do with a wooden deck? Great question!

On a site-built home, the deck often ties into the outer wall of the home. The outer wall of the home supports the weight of the deck on the side that attaches to the house. If the deck is attached to the outer wall of a manufactured home, the weight of the deck will put severe stress on the structure of the home and can cause serious problems. Remember, the weight of the outer walls of the manufactured home is not directly supported vertically by the foundation system.

When building a wooden deck for a mobile home, it is necessary to build all four sides of the deck with posts that have an adequate foundation system to transfer the weight of the deck directly into the ground; and not attach to the outer w

Number Two Issue – Undersized Joists And Beams

How many times have you been on a deck and felt it “bounce” under your weight? I’m not suggesting anything about your weight here! What I am suggesting, is that often the floor joists are undersized and not adequate to support the weight placed on the deck.

Too many times on the weekend-warrior projects, I’ve seen 2 x 4s used as the floor joists. 2 x 4s are not strong enough to support the needed weight and they are not up to code. Some areas might allow 2 x 6s to be used. A 2 x 6 would be the minimum. A much better idea would be the use of 2 x 8 floor joists for supporting the deck. Check your local building codes. Inspect your deck to see if your floor joists are sagging and are undersized. If your deck bounces or is sagging, they most likely are.

What About Floor Joist Spacing?

Even if you are using the recommended sized floor joist, you may still have a danger issue if the joists are spaced too far apart. It is not uncommon to find joists spaced at 24 inches. This is acceptable for some building codes, but we like to use 16” on centers. Check your local building codes.

When the floor joists are spaced too far apart, the wood used for the deck flooring will sag and be uneven. When the deck floor sags and is uneven, you will find lots of tripping hazards as people walk across the deck.

And the Deck Boards…

The deck boards above the joists provide the floor that will either be walked on or covered with some type of flooring. the deck boards can be anything from 1 x 4 boards cut to length to 3/4” plywood. There needs to be enough bending strength in the wood to minimize any flex in the 16” to 24″

An important point to note is that each board, whether it is a plank or plywood, needs to span at least 4 floor joists. In the outer two, it will go to the middle of the joist and be secured to the joist. It will completely cover the middle two joists and should be secured to those as well.

Although the subfloor boards can be nailed, we prefer to use screws. Nails will often loosen over time causing squeaks and movement. If plank wood is being used, then put at least 2 screws per joist; preferably 3. If plywood sheets are being used, then the screws should be placed about every 3 inches along the joist.

Have You Heard of a Ledger Connection?

The ledger board is the piece of lumber that gets bolted to the house wall and foundation on a site-built home. This secure connection to the home allows all the weight for that side of the deck to be transferred to the foundation of the house.

On a mobile home, as we mentioned above, the side of the deck near the mobile home needs to have its own vertical posts for foundation support on cement piers. Even so, there is still a ledger board on the side next to the home. A smart builder will be sure and leave enough space between the home and the deck to allow water to run off the house and down to the ground; not running onto the deck; unless of course, you’re wanting the deck to rot and decay!

We like to use a 1-inch gap between the side of the home and the ledger board on the deck. Any doorways leading from the home to the deck can have a small board that fills in the gap.

Too many times on the weekend-warrior projects, I’ve seen 2 x 4s used as the floor joists. 2 x 4s are not strong enough to support the needed weight and they are not up to code. Some areas might allow 2 x 6s to be used. A 2 x 6 would be the minimum. A much better idea would be the use of 2 x

Number Three Issue – Inadequate Railings

Any structure more than about 30 inches or more above the ground should absolutely have a railing installed for the safety of guests and family. An accidental fall off a deck can cause serious injury.

Check codes in your local area, but most railings should be installed at a height of 36” and have a space no larger than 4” between railing slats for the safety of small children. The railing should go all the way around any side of the deck where a person might be able to fall.

If you already have a deck give the railings a good shake to see how much they move. Check to see if they might give way if someone were to lean heavily against it or fall into it. If it feels weak, then it is certainly time for reinforcement.

Don’t forget about the steps. Any rise of four or more steps certainly needs a railing on at least one side as well.

Building In Structural Integrity

Even a DIY type can build a solid deck with the proper know how. It is easy these days to get on YouTube and find a good video on almost any subject.

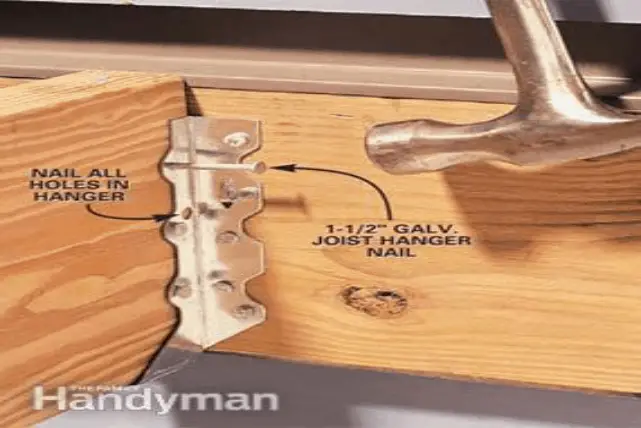

When building a deck, we see too many do-it-yourself types use nails only to build their decks. This is inadequate and will not be structurally sound as time goes by. Wood moves, movement causes nails to loosen.

The deck should be built with metal connector plates, straps, and bolts, along with a good foundation. When using metal connector plates to join the floor joists with beams, be sure that a nail is used in every hole. The connections should also be very snug.

When doing your deck inspection, any lumber on the deck that is pulling away from the connection point should be repaired immediately to prevent any further deterioration.

Deck Height Matters

Wooden decks that are either built directly on the ground or a few inches above it are doomed to have a very short life span. Water is the mortal enemy to wooden structures. Water and moisture on the ground will wick into the wooden deck and cause decay. It is especially difficult to inspect because the deck is so close to the ground. It is a good idea to try to keep the deck at least a foot above the ground where water will not come in direct contact with it.

Simpson Strong=Tie has an excellent PDF download available called “Deck Connection and Fastening Guide”.

Related Questions

HOW CAN I GET RID OF DAMPNESS AND MOLD IN MY MOBILE HOME?

Water and humidity in any home, site-built, modular, or manufactured can cause problems for any homeowner. In fact, water remediation (restoration) is a $210 BILLION dollar business in the United States. In case you’re wondering, that is A LOT!

When water gets trapped in spaces such as attics, walls, crawl spaces, carpets, wood subfloors, etc. mold can develop. Mold is a common health hazard and causes all types of respiratory issues.

Remember the old saying “an ounce of prevention is worth a pound of cure”? That is absolutely the case when it comes to getting rid of dampness and mold inside of a mobile home.

Most folks think that water damage inside of a home comes either from leaking plumbing or a leaky roof. While those are both true, that is only the beginning. Sealing out moisture, whether from the roof, windows, doors, floor, skirting or ground is necessary to prevent the buildup of dampness and mold. Keeping the moisture away, to begin with, is the ultimate weapon against the buildup of dampness and mold.

SHOULD YOU REMODEL AN OLDER MOBILE HOME?

Older manufactured homes are far less expensive to buy than a new mobile home, and a fraction of the cost of a site-built home. Whether you plan to live in the home, flip it, or buy it as a rental investment, does it make sense to invest money into an older home?

At Mobile Home Friend, our answer to this question is a RESOUNDING “YES! We have done this with homes that were given to us, homes that we paid less than $1,000 for and homes that we’ve paid up to $10,000 for. We’ve yet to lose money on any of them! We will caution that if the home is a pre-HUD (built prior to June 1976) it may not be the wisest choice.

That said, approach remodeling any mobile home with CAUTION! There are lots of things to look out for in making the decision on how much remodeling you should do.