Just like with any construction project, construction standards and regulations for Manufactured (Mobile) Homes has gotten much better over the years. Some early examples of manufactured homes were built to be easy to transport and inexpensive to build.

Just like with any construction project, construction standards and regulations for Manufactured (Mobile) Homes has gotten much better over the years. Some early examples of manufactured homes were built to be easy to transport and inexpensive to build.

The size of the studs in a mobile home can vary depending on the construction and design of the home. However, most mobile homes are built using 2×4 or 2×6 wooden studs, which are typically spaced 16 inches apart.

It’s important to note that the studs used in mobile homes may not be the same as those used in traditional stick-built homes. Mobile homes are designed to be lightweight and easy to transport, which means they often use lighter weight materials and smaller-sized studs. Additionally, mobile homes may use metal studs instead of wood studs in some areas, such as around doors and windows.

If you need to know the exact size of the studs in your mobile home, you can consult the manufacturer’s specifications or consult with a professional contractor or builder who is familiar with mobile home construction.

Table of Contents

The Short Answer

Before 1976 (HUD Standards)

- Exterior Walls – 2”x2” or 2”x3”

- Most older 12’ and 14’ wide homes used 2”x3” studs

- Very old 8’ and 10’ wide mobiles used the small 2”x2” studs

- Generally, stud spacing is 16” on center

- Interior Walls – 2”x2” are the most common

- Sometimes interior wall studs on some of them to be 1”x2”

- Stud spacing tends to be 24” on center for interior walls

- Truss Roof System (All over the map)

- Often 2”x2” or 2”x3” truss structures

- Top member of truss is often arched without a center peak

Post 1976 HUD Manufactured Homes

- Exterior Walls – 2”x4” or 2” x 6”

- 2”x3” may be available depending upon wind standards

- Spacing is almost always 16” on center

- Interior Walls – 2”x3” or 2”x4”

- Truss Roof System

- Generally 2”x4” truss systems

- Some new builders offer 2”x6” on certain models

Why Read Further?

- Insulation R values are dependent upon studs and hollow cavity depth

- Wall strength factors

- Remodeling points to consider

Insulation R-Values

What are R-Values? The better insulated a home is, roof, walls and floor, the more energy efficient the home becomes. Noise abatement is also a benefit of higher insulation factors. So what does this have to do with the size of the studs?

What are R-Values? The better insulated a home is, roof, walls and floor, the more energy efficient the home becomes. Noise abatement is also a benefit of higher insulation factors. So what does this have to do with the size of the studs?

Insulation works by trapping dead air within tiny pockets inside the insulation. The thicker the wall, the more tiny pocket the insulation can hold. In reverse, a thinner the wall will have fewer dead air pockets.

Wall studs can have an impact on the insulation R-values in a few different ways:

- Thermal bridging: Wall studs conduct heat more readily than insulation materials. This means that the studs can act as a bridge between the interior and exterior of the building, allowing heat to escape or enter more easily than if the wall was completely insulated. This phenomenon is known as “thermal bridging” and can reduce the overall R-value of the wall.

- Depth of the wall cavity: The depth of the wall cavity can also impact the insulation R-value. If the studs are wider than usual, this can result in a shallower cavity for the insulation material. This reduces the amount of insulation that can be installed and can result in a lower overall R-value.

- Type of insulation: The type of insulation used can also affect the R-value. Some insulation materials, such as spray foam or rigid foam board, can be installed directly against the studs and provide a better overall R-value than other types of insulation that require an air gap to be effective.

To minimize the impact of wall studs on insulation R-values, it’s important to use high-quality insulation materials that are properly installed and to minimize thermal bridging by using insulation techniques such as sheathing or furring. Additionally, using thinner studs or spacing them further apart can help maximize the amount of insulation that can be installed in the wall cavity.

Wall Insulation

The amount of insulation your walls can hold when done properly will determine the overall R-value rating your walls will support. This all depends upon the type of stud used for your wall framing.

The weather zone you live in will dictate the amount of wall insulation you need for a properly insulated wall. Keep in mind that older mobile homes (pre-HUD) often have exterior wall studs that are 2”x3” or even smaller in some cases. You would have difficulty in properly insulating a home in cold climates with exterior walls that are framed with studs smaller than 2”x4” studs.

The following table gives the R-values possible with 2”x4” and 2”x6” exterior wall studs:

|

Insulation Type |

Thickness of Insulation Itself |

Appropriate for Wall Type: |

|

R-13 |

3.50″ |

2 x 4 stud walls |

|

R-15 |

3.50″ |

2 x 4 stud walls |

|

R-19 |

6.25″ |

2 x 6 stud walls |

|

R-21 |

5.50″ |

2 x 6 stud walls |

Roof Insulation

Whether to keep out the cold or the heat, roof insulation is of utmost importance. For most climates, R-30 to R-40 is recommended for attic insulation. Keep in mind that the higher the R-value, the more space is needed to install it.

There is not usually any attic access in manufactured homes. This is because of the limited amount of space between the ceiling below and the roof above.

In older mobile homes, the amount of space between ceiling and roof was very narrow along the side walls. There was not much space to install a high R-value insulation product. Many of these older homes have R-values in the R-10 to R-15 range.

Many newer homes now have at least R-30 ceiling insulation values and some have options for R-38 to R-50.

Wall Strength

The size of the studs can have a significant impact on the strength of walls. Generally, larger and thicker studs will result in stronger walls, while smaller and thinner studs will result in weaker walls.

The strength of the wall depends on several factors, including the thickness and quality of the studs, the spacing of the studs, and the type and thickness of the sheathing used to cover the wall.

In general, the larger the studs, the stronger the wall will be. This is because larger studs have more surface area to distribute the weight and stress of the building, and they are less likely to bend or warp under the weight of the structure. Additionally, larger studs can support more weight and allow for larger openings such as windows and doors.

However, using larger studs can also increase the cost of construction, as well as the weight and complexity of the structure. This is why the size of the studs is often determined based on the load requirements and design of the building.

The strength of any wall is dependent not only on the materials used but also the construction methods used to build it. Manufactured homes are almost always built with wood-framed wall systems.

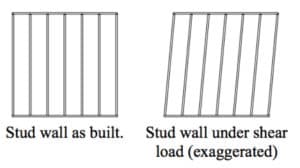

The weight of your roof causes compression loads to be placed on a load-bearing wall in your home. The additional weight of snow will compound the compression on these walls. Also, strong wind and gusts will apply shear forces on walls. Shear forces they to move the wall from the rectangle the wall was meant to be and move it to a parallelogram.

Building codes, whether local for site-built homes, or to HUD standard for manufactured homes, require that walls be built strongly enough to withstand these forces.

Building codes, whether local for site-built homes, or to HUD standard for manufactured homes, require that walls be built strongly enough to withstand these forces.

Interior Walls

Most site-built homes today are also built with wood-framed wall systems with 2”x4” or 2”x6” used the vast majority. Most site-built homes also use 16” on center studs in the outer walls and interior load-bearing walls. Most interior partition walls use 24” on center studs.

The reason many interior non-load bearing walls increase the spacing to 24” on center is that it reduces the amount of wood needed. For example, an 8’ long section of wall with 16” on center spacing will require 7 studs. If the spacing is increased to 24” on center, the number of studs can be reduced to 5. For non-load bearing walls, this will not affect the structural integrity of the home.

Manufactured homes are largely built the same. There are still manufactured homes built with 2”x3” interior wall studs, however. Keep in mind that interior, non-load bearing walls are simply dividing up the interior space of the home and are not structural.

You may question the ability of the smaller studs to carry the load of things hung on the interior walls such as cabinetry or shelving. When cabinetry is attached to an interior wall on the actual studs, the weight is transferred vertically through the stud to the flooring system. The use of the smaller studs for interior non-load bearing walls should not affect the strength or function of a home.

For homes built with interior walls using the smaller studs, the only real difference you may notice is the appearance of the wall thickness around door openings.

Remodeling Points To Consider

When doing remodeling projects to a manufactured home, you should be aware of the size of studs used in both interior and exterior walls. This becomes most important when considering the types of replacement doors or windows you may be using; especially doors.

If your manufactured home uses at least 2”x4” studs for exterior and interior walls, you should not have any issues using standard doors purchased from any big box store. Often the height of the doors may need to be cut down from their standard height if your wall systems are shorter than a typical site-built home.

On the other hand, if you own a home that uses 2”x3” studs for either the exterior or interior walls, you may have difficulty purchasing doors and frames meant for a thicker wall.

In these cases with the thinner studs, there are a number of workarounds I have used when remodeling an older mobile home using standard site-built home products.

One thing we have done with the thinner wall system is to build up the wall around the door opening on either side of the wall. This can be aesthetically pleasing in appearance. We simply use 1”x6” lumber to frame around the door. This adds the additional thickness needed for the door frame.

Conclusion

Newer manufactured homes that conform to HUD standards put in place in 1976 will provide a home that is built to weather the test of time. We have remodeled many 30 to 40-year-old manufactured homes that are structurally sound and still in excellent condition after decades of service.

Understanding the types of exterior walls, interior walls and roof truss systems in use for your home will help you to make the right decisions for purchasing or remodeling a manufactured home you have interest in.

Related Questions

- How Far Apart Are Studs In A Trailer Home? – Exterior walls are almost always 16″ on center. Many homes have 24″ on-center studs on the interior partition walls, although many are also built with 16″ on-center interior walls as well.

- How To Install A TV Mount In A Mobile Home? – There are a few considerations here. First, you need to know the stud spacing on the wall where you plan to mount the TV. If the mount allows you to go directly into the stud then mounting a TV on that wall should be fine. Using drywall anchors on a wall for TV mounting generally will not work. Many mobile homes have wall material that is 1/4″ to 3/8″ thick. there generally is not enough strength in this material to support the weight with drywall anchors alone.