Table of Contents

Introduction

I have spent over two decades in the trenches of the manufactured housing industry. During that time, I have flipped more than 100 properties. I have seen homes that settled so poorly the front door wouldnt lock and others that stood firm through decades of shifting soil. The difference always comes down to what is happening underneath the skirting. If you get the foundation wrong, nothing else matters. You can spend $50,000 on quartz countertops and luxury vinyl plank flooring, but if your piers are sinking, your investment is bleeding out. In this guide, I am going to break down every major foundation type with the hard logic I use when evaluating a deal.

Video Guide Overview

Affiliate Disclosure

I believe in transparency. Some of the links in this article are affiliate links. This means if you click a link and purchase a product, I receive a small commission at no extra cost to you. I only recommend tools and hardware that I have personally used on my job sites or in my own rental portfolio. These commissions help keep MobileHomeFriend.com a free resource for the community.

The Short Answer

The best foundation for a mobile home depends on your budget, your local climate, and whether you want the home classified as real property for financing. Pier and Beam foundations are the most common and cost effective, utilizing steel jacks or concrete blocks on footings. Slab foundations provide a solid concrete surface that improves stability and prevents moisture issues from the ground. Basement foundations are the most expensive but offer massive square footage gains and the highest resale value. If you are looking for the best balance of cost and long term stability, a reinforced slab is my personal recommendation for most investors.

The Engineering Logic of Manufactured Home Foundations

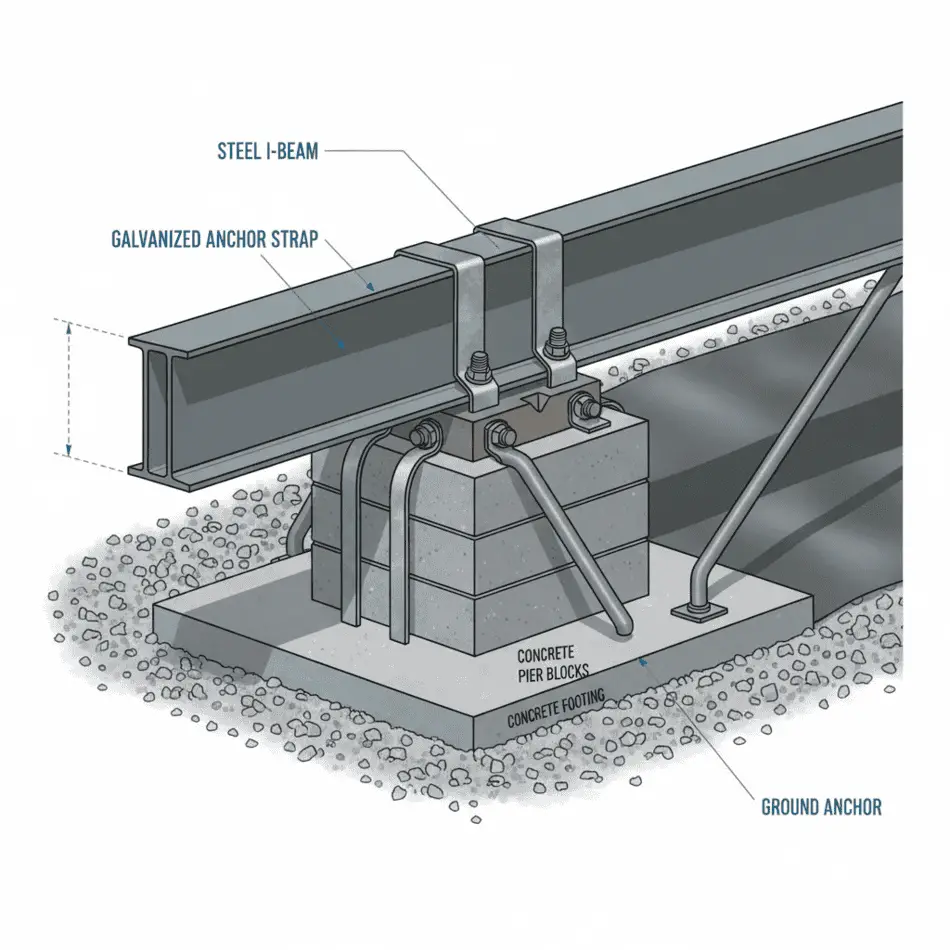

Before we dive into the specific types, you must understand the physics at play. A manufactured home is built on a steel chassis. Unlike a site built home where the weight is distributed across a continuous perimeter wall, a mobile home distributes its weight primarily through the heavy steel I beams running the length of the unit. This creates concentrated point loads. If your foundation cannot support these point loads, the steel frame will flex. When the frame flexes, your drywall cracks, your windows stick, and your plumbing joints start to leak. We are fighting two main enemies: soil compression and frost heave.

Soil Bearing Capacity

Every piece of land has a specific bearing capacity measured in pounds per square foot. Sandy soil behaves differently than heavy clay. When I walk a property, I am looking for signs of poor drainage. If water pools near the home, the soil softens. Soft soil leads to settlement. Regardless of the foundation type you choose, the preparation of the “pad” is the most critical step. I always insist on a compacted gravel base under any concrete work to ensure water moves away from the load bearing points.

Frost Heave and Local Codes

If you live in a northern climate, the water in the soil freezes and expands. This expansion can lift a 20,000 pound home section several inches. This is why local building codes require footings to be placed below the frost line. In some areas, this means digging down four feet. In Florida, it might only be a few inches. Never skip the permit process on a foundation. If you do, you will find it nearly impossible to sell the home later because no appraiser will sign off on it.

Deep Dive: Pier and Beam Foundations

This is the standard for the industry. It is the fastest to install and the most forgiving for tight budgets. In a pier and beam setup, the home sits on a series of columns spaced according to the manufacturers installation manual. These columns are typically made of stacked concrete blocks or heavy duty steel jack stands.

Concrete Block Piers

I prefer concrete blocks over steel jacks for long term holds. We use 8x8x16 inch blocks. For homes higher than 36 inches, you must double stack the blocks and interlock them for lateral stability. The blocks sit on a footing, which could be a pre cast ABS plastic pad or a poured concrete pad. The main advantage here is cost. The disadvantage is that blocks can shift over time, requiring the home to be releveled every few years.

Steel Jack Stands

These are common in parts of the country like California. They are easy to adjust with a large threaded bolt at the top. While they make leveling a breeze, they are prone to rusting if the humidity under the home is not controlled. I have seen 15 year old jacks that were so corroded they were structurally unsound. If you go this route, ensure you are using galvanized steel and keep your vapor barrier intact.

The Importance of Tie Downs

A pier foundation only handles vertical loads. It does nothing to stop the home from blowing over in high winds. You must use ground anchors and steel straps. These anchors are screwed deep into the earth and cinched to the frame. In my experience, most older homes have loose straps. This is a massive safety risk. Every time I flip a home, I have a technician retighten every single anchor to the proper torque specs.

Deep Dive: Slab Foundations

A concrete slab foundation is often referred to as a “floating slab.” It is a continuous pour of concrete that covers the entire footprint of the home. This is a massive upgrade over piers for several reasons. First, it creates a clean, dry environment under the home. Second, it distributes the weight of the home over a much larger surface area, which virtually eliminates the risk of individual piers sinking.

The Construction Process

When we pour a slab for a double wide, we start by excavating the topsoil. We lay down 4 to 6 inches of compacted gravel. Then we install a thick vapor barrier. We use rebar reinforcement to ensure the concrete doesnt crack under the weight of the home. The slab is typically 4 to 6 inches thick, with thickened “ribs” or footings directly under where the I beams will sit. This is called a monolithic pour.

Moisture Control and Longevity

One of the biggest killers of mobile homes is under belly rot. When a home sits on bare dirt, moisture evaporates from the ground and gets trapped against the wooden floor joists. A slab stops this process entirely. When I buy a home that has been on a slab for 20 years, the insulation and wooden belly board usually look brand new. This longevity is why I often steer my students toward slabs for their forever homes.

Deep Dive: Basement Foundations

This is the “gold standard.” Putting a manufactured home on a basement essentially turns it into a traditional site built house in the eyes of the bank. This is often called a Permanent Foundation. It requires a specific type of manufactured home designed for “perimeter loading.”

Perimeter Loading vs. Frame Loading

Most mobile homes are frame loaded, meaning the weight is on the center I beams. To put a home on a basement, the manufacturer must build the home so the exterior walls carry the weight. This allows the home to sit on the basement walls just like a stick built house. If you try to put a standard frame loaded home on a basement, you have to install massive heavy duty steel cross beams to support the center, which adds significant cost and complexity.

The Financial Advantage

The cost of a basement is high, often exceeding $40,000 in todays market. However, you are doubling your square footage. A 1,500 square foot double wide suddenly becomes a 3,000 square foot home. In markets where land is expensive, this is a brilliant move. It also makes the home eligible for FHA and VA loans more easily, as it meets the strictest “permanency” requirements. I have seen homes on basements sell for 40% more than the exact same model on a pier foundation.

Cost Transparency Table (2026 Estimates)

Prices have shifted significantly over the last few years due to labor shortages and material costs. These figures represent averages for a standard 28×60 double wide home.

| Foundation Type | Estimated Cost | Typical Timeline | Best For |

|---|---|---|---|

| Pier and Beam | $4,500 – $8,000 | 1-2 Days | Budget-conscious / Parks |

| Concrete Slab | $12,000 – $18,000 | 3-5 Days | Long-term rental / High humidity |

| Full Basement | $45,000 – $70,000 | 3-5 Weeks | Equity growth / Large families |

| Pit Set (Slab) | $15,000 – $22,000 | 1 Week | Low-profile “site-built” look |

Recommended Installation Gear

If you are managing your own install or doing a DIY relevel, you need the right tools. I have used dozens of different brands, and these three are the ones I keep in my truck at all times.

| Product Name | Use Case | Why I Recommend It |

|---|---|---|

| LevelMaster 20-Ton Hydraulic Jack | Releveling and pier adjustment | Most standard jacks fail under the concentrated load of a double wide frame. This unit has a wide base that prevents tipping on soft dirt. |

| Tite-Anchor Torque Wrench Kit | Installing and checking tie-downs | Hand tightening straps is a waste of time. This kit ensures your anchors meet HUD wind zone requirements. |

| Hydro-Shield 20mil Vapor Barrier | Ground moisture control | Standard 6mil plastic tears too easily. This reinforced 20mil barrier can withstand being crawled on during repairs without puncturing. |

Actionable Foundation Checklist

When you are inspecting a foundation or preparing for a new install, follow these steps. I use this exact sequence for every property I evaluate.

- Check for Standing Water: Walk the perimeter. If you see moss or damp soil, you have a drainage issue that will undermine any foundation type.

- Verify Footing Depth: Ensure the footings are below the local frost line. Ask the contractor for a “depth photo” before they pour.

- Inspect Pier Spacing: Refer to the manufacturers charts. Typically, piers should be every 8 to 10 feet along the main I beams.

- Look for “Spalling”: On concrete slabs or blocks, look for flaking or crumbling. This indicates a poor mix or salt damage.

- Test the Skirting Vents: A foundation is only as good as its ventilation. You need 1 square foot of venting for every 150 square feet of floor space.

- Tighten Tie-Downs: Use a wrench to check that straps are taut. If they are loose, the home can “walk” off its piers in a storm.

- Check Door Alignment: If the interior doors are sticking, the foundation has already shifted. This is your first warning sign.

Internal Resources

To deepen your understanding of manufactured home maintenance and setup, check out these other guides I have written:

- The Complete Guide to Mobile Home Releveling Costs

- How to Install Skirting That Lasts 20 Years

- Understanding HUD Wind Zones and Anchor Requirements

Summary

Your foundation choice is a decision about the future of your property. If you are looking for a quick flip in a park, a professionally installed pier and beam system is perfectly adequate. If you are putting a home on private land and want it to appreciate like a traditional house, you should invest in a concrete slab or a full basement. The money you spend today on concrete and steel will save you thousands later in drywall repairs, floor leveling, and structural headaches. Do not cut corners here. The earth is always moving, and your foundation is the only thing keeping your investment from moving with it.

About Chuck O’Dell

Chuck O’Dell is the founder of MobileHomeFriend.com and a veteran real estate investor with over 20 years in the manufactured housing sector. Having managed over 100 successful property flips and a sizable rental portfolio, Chuck focuses on teaching homeowners and investors how to navigate the technical and financial hurdles of mobile home ownership with no fluff and direct, actionable advice.

“Drawing on over two decades of hands-on industry experience, Chuck O’Dell breaks down the technical nuances of manufactured home foundations to help homeowners ensure long-term structural integrity.”