Written by Chuck O’Dell in Finances, Maintenance, Repairs and Remodels

(Updated December 1, 2025) A leak in your mobile home roof is more than just an inconvenience; it’s a direct threat to your home’s structure and value. Unlike stick-built homes, manufactured home roofs often rely on durable, but single-layer metal or rubberized systems, making annual inspection and timely repair absolutely critical. As an investor, I’ve spent thousands fixing deferred roof maintenance, and I can tell you exactly where your money should go. This guide breaks down the complete national cost for repair, from the smallest seam sealing job to a full structural replacement, ensuring you get the most long-lasting solution for your investment.

Table of Contents

The Short Answer

The cost for mobile home roof repair varies dramatically based on the scope: a simple seam sealing and coating job averages between $1,500 and $3,500. However, a complete replacement of the roof membrane or installing a new peaked (shingle) roof averages between $5,000 and $12,000. The cheapest and best long-term solution is preventative maintenance using high-quality elastomeric coatings every 5-7 years.

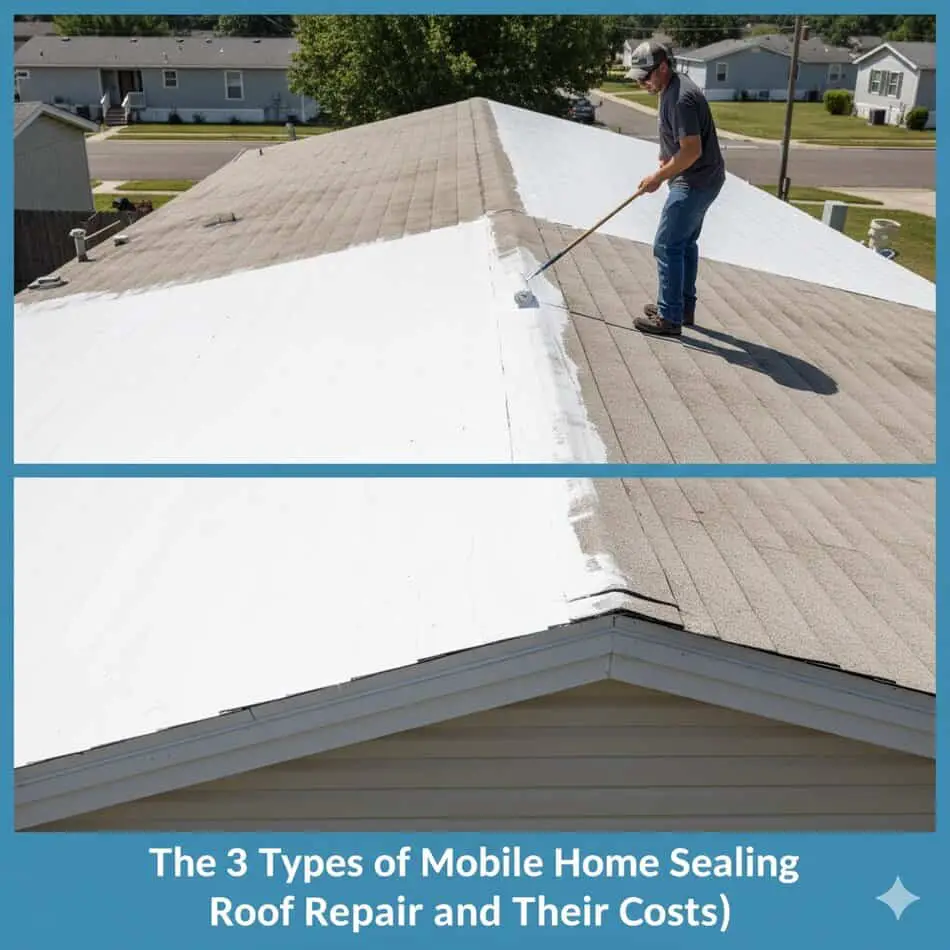

The 3 Types of Mobile Home Roof Repair and Their Costs

Mobile home roofs typically fall into two categories: the low-slope or flat metal roof (common on older models) and the shingled peaked roof (common on newer models). Repair methods—and costs—differ based on which system you have.

1. Roof Coatings and Sealing (The Preventative Fix)

Roof coatings are your first line of defense. They are the cheapest, most common, and most crucial maintenance step you can take. These coatings (usually white or light-colored) are applied directly over the existing roof material to seal pinholes, prevent seam separation, and reflect heat (reducing summer cooling costs).

| Scope of Work | Average Cost Range (2025) | Longevity |

|---|---|---|

| DIY Seam Sealing (Materials Only) | $250 – $500 | 1–3 Years |

| Professional Elastomeric Coating (Labor & Materials) | $1,500 – $3,500 | 5–10 Years |

| Professional Silicone Coating (Premium) | $3,000 – $6,000 | 15+ Years |

Expert Note: Always choose an elastomeric or silicone coating. Standard asphalt-based coatings dry out quickly and crack, often leading to more problems than they solve. Silicone is superior but requires a perfectly clean surface.

2. Membrane or Metal Panel Replacement (The Structural Fix)

If your roof has major structural damage—large holes, severe rust, or failed seams that lead to waterlogged decking—coating won’t be enough. You will need to replace the entire covering layer, whether it’s the metal roofing or a flexible TPO/EPDM membrane used on some flat roofs.

- Replacing Metal Panels: Cost typically depends on the gauge of the new metal and the extent of the purlin (support beam) damage underneath. A partial replacement can run $2,500 to $6,000.

- Replacing TPO/EPDM Membrane: This is a common solution for restoring flat roofs. The cost usually runs between $4.00 and $7.00 per square foot, totaling $4,000 to $8,000 for a typical double-wide home.

3. Installing a Peaked Roof Over (The Value-Added Upgrade)

The single best improvement you can make to both the longevity and financial value of your mobile home is installing a full peaked (pitched) roof over the existing flat roof. This upgrade prevents water pooling, allows for traditional gutter installation, and provides an attic space for better insulation and ventilation.

- Cost Range: Expect to pay between $6,000 and $15,000. The final price depends on the pitch, the complexity of the truss system, and whether you choose traditional shingles or metal roofing.

- Financial Benefit: This upgrade is key to maximizing resale value and securing the best financing, as it makes the home look and function much more like a stick-built house, which helps with FHA and conventional appraisals.

Diagnosing the Leak: Key Indicators of Roof Failure

Finding the source of a leak is often harder than fixing it. Water rarely drips directly below the entry point; it travels along beams and wiring before hitting the ceiling.

Common Failure Points:

- Separated Seams: On metal roofs, the points where panels overlap are sealed with caulk or tape. Over years of thermal expansion and contraction, these seams dry out, crack, and separate. This is the #1 source of leaks on older metal roofs.

- Vent and Flashing: Any penetration through the roof—vents, chimneys, HVAC—requires flashing, which is sealed with caulk. This caulk fails first. Always check the flashing before looking at the main roof surface.

- Damage from Expansion and Contraction: Mobile home roofs endure extreme temperature shifts. This movement can loosen fasteners and cause pinholes in the membrane or micro-cracks in the metal, which are hard to spot until the leak begins.

🚨 Charles O’Dell’s Warning Signs of Structural Damage

Don’t just look up! Structural roof damage shows itself in secondary ways that require immediate attention:

- Sagging Ceiling Panels: A severe and urgent sign. The ceiling panels are absorbing water from the decking above. This means the decking is already saturated and potentially rotting.

- Mold or Musty Odors: If you detect a pervasive musty odor in a closet or near an exterior wall, water is likely sitting in the insulation or wall cavities, causing wood rot and mold growth.

- Loose Siding/Gutters: If your gutters are pulling away or exterior siding is loose near the roofline, it suggests water is running off the roof improperly or is wicking into the fascia board.

The Critical Role of Insurance and Resale Value

Just like the foundation, your roof has a massive impact on your home’s financial viability.

Lender Requirements for Roof Condition

If you are applying for an FHA or Conventional loan, the appraiser will conduct a detailed roof inspection. The appraiser must confirm the roof has at least two years of useful life remaining. If the roof is badly oxidized, has severe ponding, or is clearly leaking, the lender will require a certified repair or replacement before they will close the loan.

Expert Tip: If you plan to sell or refinance within the next five years, invest in a quality silicone coating (15-year life) now. It will pay for itself by eliminating appraisal issues later.

Homeowner’s Insurance

Roof work can be highly dangerous, especially on low-sloped roofs where water pooling creates slick surfaces. While simple tasks can be DIY, professional help is generally required for structural integrity.

Standard mobile home policies typically cover sudden, unexpected damage (like a tree falling or damage from a covered storm). However, they will not cover damage caused by lack of maintenance or slow deterioration (like a slowly leaking seam). If your adjuster finds the leak was due to aging sealant, your claim may be denied, and you’ll pay for the ceiling repair out of pocket.

Internal Link Opportunity: The integrity of the roof is vital for protecting your foundation and meeting FHA standards. Learn the high-stakes requirements here: How to Qualify for a Mobile Home FHA Loan and Mobile Home Foundation Repair Costs: The Complete Price Guide.

DIY vs. Professional Contractor: When to Call the Experts

DIY Tasks (Recommended)

- Basic Cleaning: Clearing debris, mold, and mildew off the roof surface.

- Minor Spot Patching: Applying small patches of roof cement or sealant tape to obvious, small holes or around a single vent pipe.

Professional Tasks (Mandatory)

- Full Surface Coating: Professional contractors have the equipment and high-grade materials to ensure an even, long-lasting coat over the entire surface.

- Decking Replacement: Any repair requiring replacing the wooden roof decking (plywood or OSB) where water damage has occurred. This is structural work and requires expert alignment.

- Peaked Roof Installation: The truss system for an over-roof requires engineering knowledge to ensure proper load bearing and attachment to the main chassis.

Affiliate Opportunity: Recommended Coating Products and Tools

For DIY and professional use, not all products are created equal. As a homeowner, you want materials designed to handle the thermal movement specific to manufactured homes.

- Elastomeric Coatings: Look for products with high solids content (50%+) and a high elongation rating, ensuring they stretch with the roof. [Affiliate Link to Recommended Elastomeric Product]

- Seam Sealant Tape: For quickly and effectively sealing separated metal seams, butyl rubber tape is far superior to caulk. [Affiliate Link to Recommended Butyl Tape]

- Professional Tools: High-powered pressure washers (used on low settings) and commercial-grade application rollers are essential for getting the longest life out of a coating job.

Related Questions (FAQ)

How long does a mobile home roof last?

A typical factory-installed metal or TPO/EPDM roof lasts 15 to 25 years. However, without proper coating maintenance, leaks can begin in as little as 10 years. A new shingled peaked roof can last 25 to 40 years—the same as a stick-built home.

What is the difference between an elastomeric and a silicone coating?

Elastomeric (Acrylic) coatings are cheaper and easier to apply, but they must be applied thickly and should not be used in constantly wet areas. Silicone coatings cost more, require less material, and are highly resistant to ponding water, making them ideal for truly flat roofs.

Can I put a metal roof over my existing mobile home roof?

Yes. Installing a metal over-roof is one of the most durable and long-term solutions. It requires building a simple truss system over the existing roof to create an air gap (for ventilation) and a slope (for drainage). The metal roof panels are then secured to the new trusses.

Summary: Timely Coating is Key to Value

The single best thing you can do to manage mobile home roof repair costs is to invest in preventative maintenance every 5 to 7 years. A simple $2,500 professional elastomeric coating job can prevent a catastrophic $10,000 structural repair down the line. Treat roof coating like a recurring maintenance cost, similar to painting a deck or clearing gutters. By prioritizing timely coating and choosing permanent materials like silicone or installing a peaked roof, you eliminate one of the biggest red flags lenders and buyers look for, protecting your investment for decades to come.

Written by a mobile home investor who has personally overseen and budgeted hundreds of roof repair and replacement projects since 2003, specializing in cost-effective longevity.