Table of Contents

Introduction

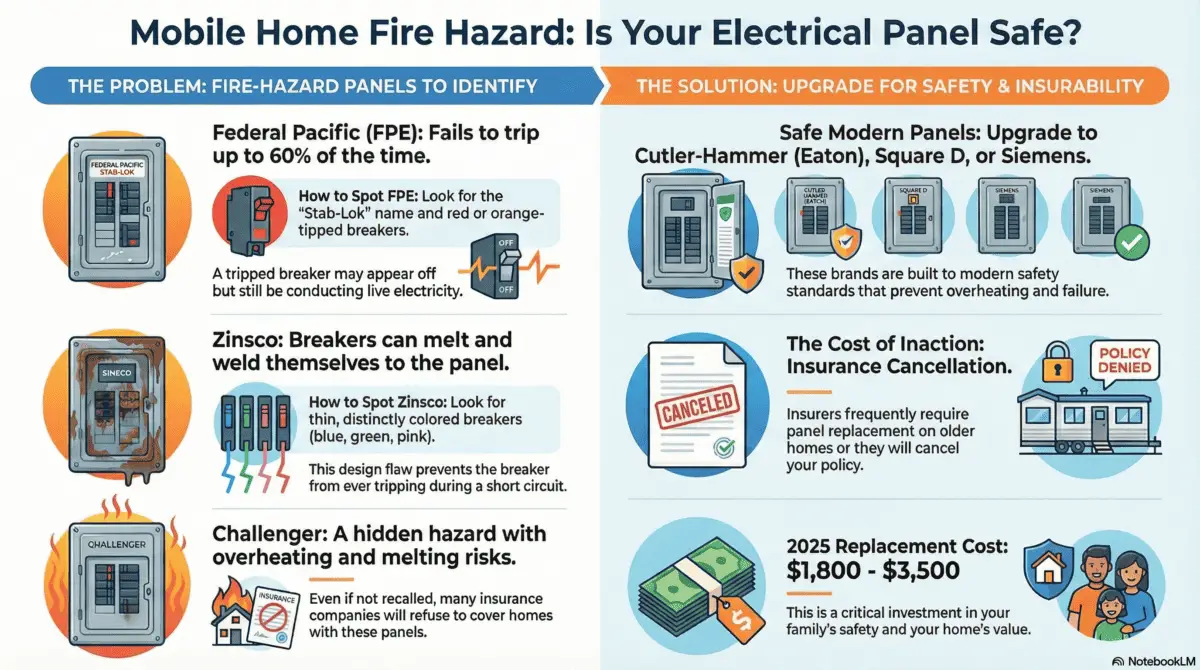

If you own an older mobile home, specifically one built before the late 1990s, the metal box in your hallway or utility closet might be the most dangerous item in your house. Electrical panels are the central nervous system of your mobile home, and for decades, manufacturers used brands that we now know are latent fire hazards. This is not about fear-mongering; this is about engineering failure rates and thermal dynamics.

In this article, I am going to walk you through the specific brands you need to look for—Federal Pacific, Zinsco, and Challenger—and explain exactly why they fail. I will also discuss Cutler-Hammer and other safe replacements. By the time you finish reading, you will know how to identify your panel, understand the cost implications of replacing it in 2025, and know whether your current setup is rendering your home uninsurable.

Affiliate Disclosure

I have included links to products in this article that I have used or found helpful. As an affiliate, I may earn a commission if you purchase through these links, at no extra cost to you. This helps support the site and allows me to continue providing free, data-driven content.

The “Short” Answer

If you do not have time for the technical deep dive, here is the bottom line: If you have a Federal Pacific or Zinsco panel, replace it immediately. These panels have extremely high failure rates where breakers fail to trip during an overload, causing the wires to overheat and catch fire. They are effectively switches, not safety devices.

If you have a Challenger panel, you are likely in a grey area; some are recalled, some are fine, but they are generally considered obsolete. If you have a Cutler-Hammer, Square D (QO or Homeline), or Siemens panel, you are generally safe, provided the wiring is sound. Expect to pay between $1,800 and $3,500 for a professional panel swap in 2025, depending on whether you need a new meter base and service entrance.

Why Mobile Homes Have Specific Panels

Mobile homes are constructed in factories under HUD codes, which differ slightly from the NEC (National Electrical Code) used for stick-built homes, though they parallel each other closely. In the 1970s and 80s, mass production demanded speed and low cost. Brands like Federal Pacific Electric (FPE) and Zinsco offered cheaper bulk pricing to manufacturers. This is why you see a disproportionate number of these specific defective panels in mobile homes compared to site-built housing from the same era.

When I bought my first park model for a flip, I didn’t even look at the panel. I assumed electricity was electricity. Three weeks later, my electrician refused to touch the rest of the wiring until the “firebox” in the closet was gone. That was my expensive introduction to brand-specific electrical risks. I learned quickly that saving money on the initial purchase price often means inheriting a liability.

The “Fire Starter” Panels: Federal Pacific & Zinsco

Federal Pacific Electric (FPE) Stab-Lok

Federal Pacific is arguably the most notorious name in electrical safety. Millions were installed from the 1950s to the 1980s. The specific line you need to look for is Stab-Lok.

Identification:

Look for the name “Federal Pacific” or “FPE” on the door cover. Inside, the breakers often have orange or red paint on the tips of the handles. The label “Stab-Lok” is usually printed between the rows of breakers.

The Failure Mode:

The Consumer Product Safety Commission (CPSC) closed its investigation into FPE in the 80s due to budget issues, not because the panels were safe. Independent testing later proved that FPE Stab-Lok breakers fail to trip up to 60% of the time when overloaded. Furthermore, they are prone to “lock-up,” where a tripped breaker appears off but is actually still conducting electricity.

Zinsco (and GTE-Sylvania)

Zinsco panels are distinct but equally dangerous. After Zinsco was sold, they were rebranded as GTE-Sylvania, so you might see either name.

Identification:

These are easy to spot. The breakers are usually thin and colorful—often pink, blue, green, or yellow. They look much different than the standard black switches you see today. The panel is also generally narrower than modern load centers.

The Failure Mode:

Zinsco breakers have a design flaw in the connection to the bus bar (the metal strip that powers the breakers). The connection becomes loose, leading to arcing (sparks) and heat. Over time, the breaker welds itself to the bus bar. I once tried to pull a Zinsco breaker out of a panel in a 1978 double-wide, and the plastic casing crumbled in my hand while the metal clip stayed fused to the back of the box. If that circuit had shorted, the breaker would never have cut power.

For those looking to inspect their own systems safely, a non-contact voltage tester is a mandatory tool.

| Product Name | Why It Is Useful | Affiliate Link |

|---|---|---|

| Fluke 1AC-II Non-Contact Voltage Tester | Allows you to verify if power is flowing without touching bare wires. Essential for initial safety checks. | Check Price |

| Klein Tools ET310 Circuit Breaker Finder | Helps you map out which breaker controls which outlet, vital when auditing an old panel. | Check Price |

| Square D Homeline 100 Amp Load Center | A standard, high-quality replacement panel often used in mobile home retrofits. | Check Price |

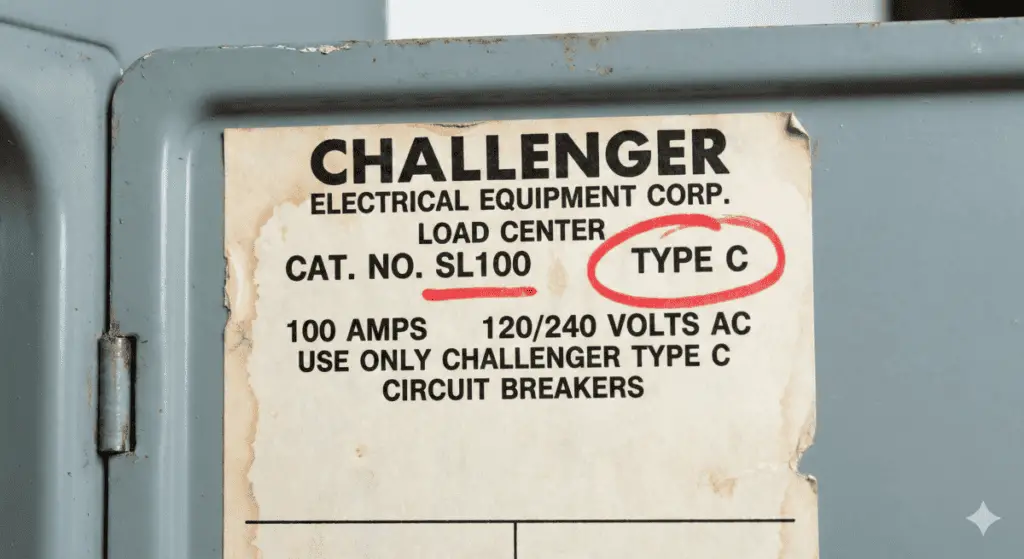

The Challenger Panel: The Hidden Hazard

Challenger panels were widely used in the 1980s and 90s. While not as universally demonized as FPE, they have a specific failure point that makes them a liability.

The Issue:

Certain Challenger breakers (specifically Types HAGF and Type C) were recalled because they overheated. However, the bigger issue is the bus bar design. Similar to Zinsco, the connection points can overheat and melt. While you can sometimes retrofit a Challenger panel with new, compatible Eaton/Cutler-Hammer breakers to make it safer, many insurance companies are now adding Challenger to their “do not bind” list.

If you are planning major renovations, such as those discussed in our guide to mobile home remodeling, replacing a Challenger panel should be part of the budget. It makes no sense to put new drywall and paint over a latent electrical hazard.

Cutler-Hammer and Modern Standards

When we talk about what you should have, Cutler-Hammer (now part of Eaton) is a primary standard. Along with Square D (Schneider Electric) and Siemens, these are the panels you want to see.

Why They Are Safer:

Modern panels use better materials for bus bars (often copper or plated aluminum) and have breakers with superior trip curves and arc extinguishing capabilities. If you are looking at a mobile home to buy and you see a grey box with a big “Square D” or “Eaton” logo, that is a significant value add. It means a previous owner likely already paid the $2,000+ to upgrade the system.

If you are upgrading, ensure you choose a panel that fits the form factor of your mobile home walls. Mobile home walls are often 2×4 or even 2×3 construction, meaning a standard residential “deep” panel might stick out of the wall. Mobile home specific panels are often designed with shallower enclosures.

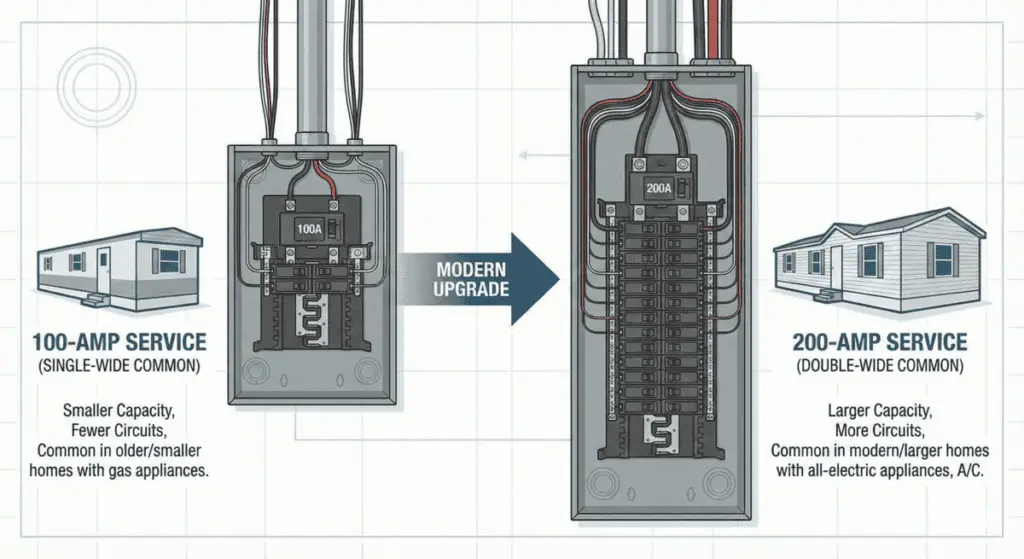

Single-Wide vs. Double-Wide Differences

The type of home you have dictates the amperage you likely have, which dictates the complexity of a panel swap.

Single-Wides (Usually 100 Amp)

Most older single-wides operate on 100-amp service. The panel is often located in a hallway or a utility closet near the back door. In very old units (pre-1976), you might even find 60-amp service, which is functionally obsolete for modern living. You cannot run a central AC, a microwave, and a hair dryer on 60 amps without tripping the main.

Double-Wides (Usually 200 Amp)

Double-wides generally have 200-amp service because they have more square footage and usually electric furnaces. The panel is often larger and handles more circuits. However, I have seen early 80s double-wides that were factory-equipped with dual 100-amp panels or a single 150-amp FPE panel. Upgrading a double-wide panel is more labor-intensive simply because there are more circuits to label, disconnect, and reconnect.

If you are unsure about the amperage requirements for your specific appliances, review our article on common mobile home electrical questions to better understand load calculations.

The Cost of Inaction: Insurance and Fires

Beyond the physical danger, there is a financial reality: Insurance Audit Failure. Many insurance carriers now require a 4-point inspection for homes over a certain age (often 20 or 30 years). If the inspector snaps a photo of a Federal Pacific or Zinsco panel, the carrier will likely issue a cancellation notice giving you 30 days to replace it or lose coverage.

I recently helped a friend who bought a 1984 Fleetwood. He got a great deal, paying cash. He called to get insurance, and the agent asked for a photo of the panel. He sent it. The agent called back two minutes later: “We can’t write this.” It was a Zinsco. He had to scramble to find an electrician who could do the job that week, paying a premium for the rush. He ended up paying $3,200 for a job that should have cost $2,200, just to get the paperwork signed.

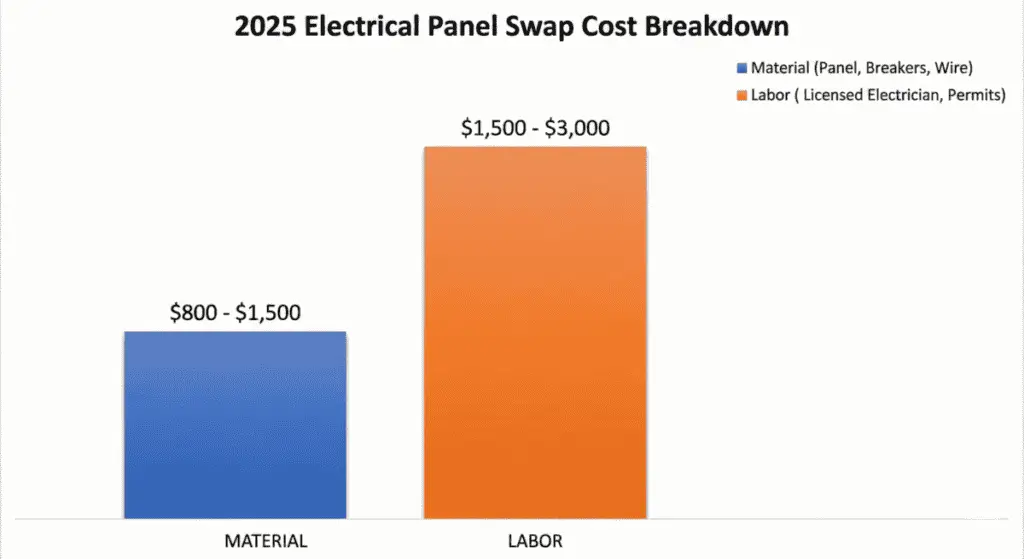

Cost Transparency: 2025 Pricing

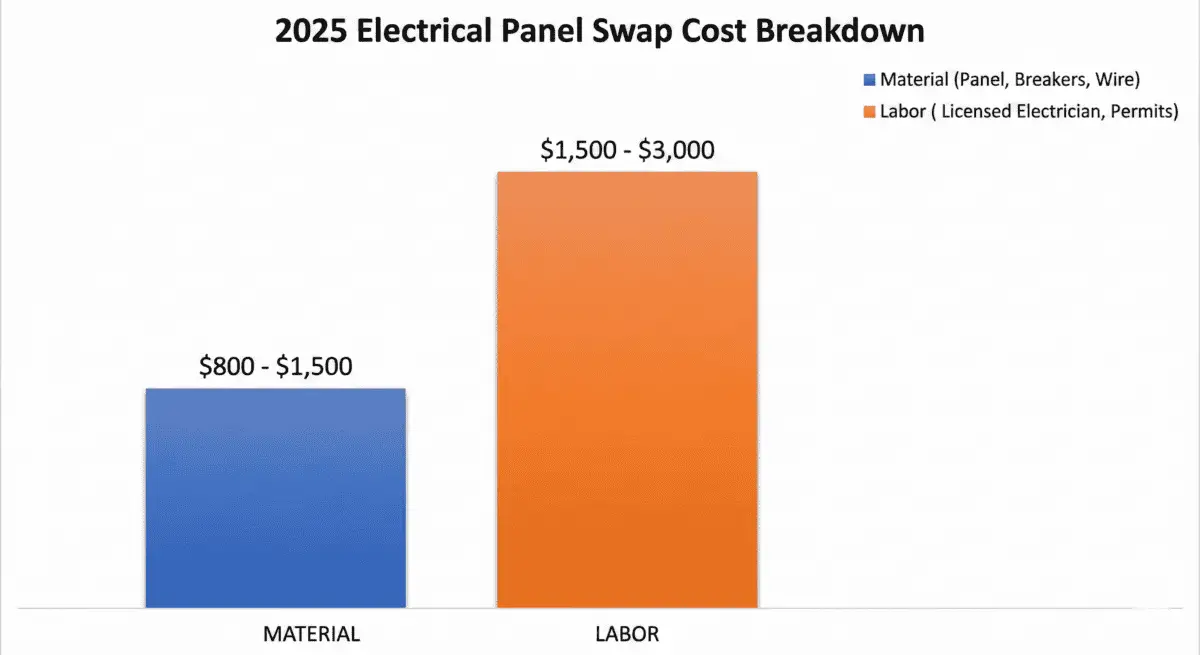

We need to be realistic about costs. Inflation has driven up the price of copper wire and skilled labor. Below is the breakdown you should expect for replacing a panel in a mobile home. This assumes a standard change-out where the location of the panel does not change.

| Item | Estimated Cost (Low) | Estimated Cost (High) | Notes |

|---|---|---|---|

| New Panel & Breakers | $250 | $500 | Includes main breaker + AFCI/GFCI breakers (code requirement). |

| Meter Base (Exterior) | $150 | $400 | Often required to be replaced simultaneously by utility. |

| Permit Fees | $100 | $350 | Varies wildly by municipality/county. |

| Labor (Electrician) | $1,200 | $2,500 | Depends on complexity and local rates. |

| Total Estimate | $1,700 | $3,750 | Budget for the high end to be safe. |

Note on DIY: Changing a panel involves working with the main service feed, which is always live unless disconnected at the pole by the utility company. This is not a DIY job. Do not attempt to save $1,500 by risking electrocution. Hire a licensed electrician.

Technical Consideration: Aluminum Wiring

While we are discussing panels, we must address the wiring attached to them. Many mobile homes with FPE or Zinsco panels also have aluminum branch wiring. Aluminum expands and contracts differently than copper, leading to loose connections.

When you replace the panel, the electrician must treat the ends of the aluminum wires with an anti-oxidant compound (like Noalox) and torque them correctly into the new breakers. Ensure your new breakers are rated CO/ALR (Copper/Aluminum Revised). If you use standard copper-only breakers with aluminum wire, you are swapping one fire hazard for another.

Summary

Your mobile home’s electrical panel is not just a grey box; it is a critical safety component. If you identify a Federal Pacific or Zinsco panel, you need to plan for a replacement immediately. These panels have a documented history of failing to trip during overloads, leading to fires. Challenger panels are a secondary concern but often require replacement due to overheating risks.

While the cost of $1,800 to $3,500 is significant, it is an investment in the longevity of your home and the safety of your family. It is also often a prerequisite for obtaining property insurance. Check your panel today, take a photo, and compare it to the descriptions in this article.

Related Questions

Can I just replace the bad breakers in a Federal Pacific panel?

Technically, aftermarket “safe” breakers exist, but they are expensive, and they do not solve the problem of the panel’s bus bar design or the stigma from insurance companies. Most experts agree that a full panel swap is the only true fix.

Do I need a permit to change my mobile home electrical panel?

Yes. Almost every jurisdiction requires a permit and an inspection for a service change. The power company will usually cut power for the work and will not turn it back on until an inspector has signed off on the new panel.

How long does a panel replacement take?

A competent electrician can usually swap a panel in a mobile home in 4 to 8 hours. You will be without power for most of the day.

About the Author

Chuck O’Dell is a real estate investor and former contractor who specializes in mobile home flipping and renovation. He has inspected, bought, and renovated hundreds of manufactured homes, dealing with everything from leaky roofs to dangerous electrical systems. He operates MobileHomeFriend.com to help homeowners navigate the unique challenges of mobile home maintenance.

Chuck O’Dell is a mobile home investor and renovator with decades of experience managing electrical upgrades and safety inspections for manufactured housing.