Table of Contents

Introduction

If you live in a mobile home built between the mid-1960s and the mid-1970s, there is a high probability that your walls are filled with aluminum wiring. This material has a terrifying reputation in the real estate and insurance industries. You may have heard stories of outlets melting, hidden fires inside walls, or insurance companies refusing to cover homes with this specific electrical setup.

The goal of this article is to strip away the panic and look at the engineering reality. You will learn exactly why aluminum acts differently than copper, how to identify it without tearing apart your walls, and the specific, code-compliant ways to fix it. We are not just going to tell you it is bad; we are going to tell you how to manage the risk and what it costs to sleep soundly at night.

Video Guideline Overiew

Affiliate Disclosure

This article contains affiliate links. If you purchase products through these links, I may earn a small commission at no extra cost to you. This helps support the site and allows me to continue providing free, data-driven content for mobile home owners.

The “Short” Answer

Is aluminum wiring dangerous? The direct answer is yes, but only if the connections are neglected or improper. The aluminum wire itself conducts electricity perfectly fine. The danger lies entirely at the connection points—where the wire wraps around a screw on an outlet, switch, or breaker.

Aluminum is softer and expands more than copper when heated. Over years of power cycling (turning lights on and off), the wire can wiggle loose from its terminal. A loose connection causes electrical arcing, which creates intense heat and can ignite surrounding materials. If your home has aluminum wiring, you do not necessarily need to rip it all out, but you must retrofitting your connections using approved methods like AlumiConn connectors or COPALUM crimps. Ignoring it is gambling with fire safety.

The Physics of the Problem: Why Aluminum Fails

To understand the fix, you have to understand the failure mechanism. It is not magic; it is metallurgy. When electricity flows through a wire, it generates heat. When materials get hot, they expand. When they cool down, they contract.

Thermal Expansion and “Creep”

Aluminum expands and contracts at a significantly higher rate than the copper or brass screws usually found on electrical outlets. This constant movement creates a phenomenon called “Cold Flow” or “Creep.” Imagine the wire expanding and pushing against the screw. Since the wire is soft, it deforms or flattens out. When it cools and shrinks, it pulls back, but now it is thinner than before. This leaves a microscopic gap between the wire and the screw.

Oxidation and Arcing

Once that gap exists, electricity has to jump across it. This is called arcing. Arcing reaches temperatures that can exceed 10,000°F. Furthermore, when aluminum is exposed to air, it forms aluminum oxide. Unlike copper oxide (which conducts electricity), aluminum oxide is an electrical insulator. As the wire corrodes, resistance increases, heat increases, and you eventually get a melted outlet or a fire inside the wall cavity.

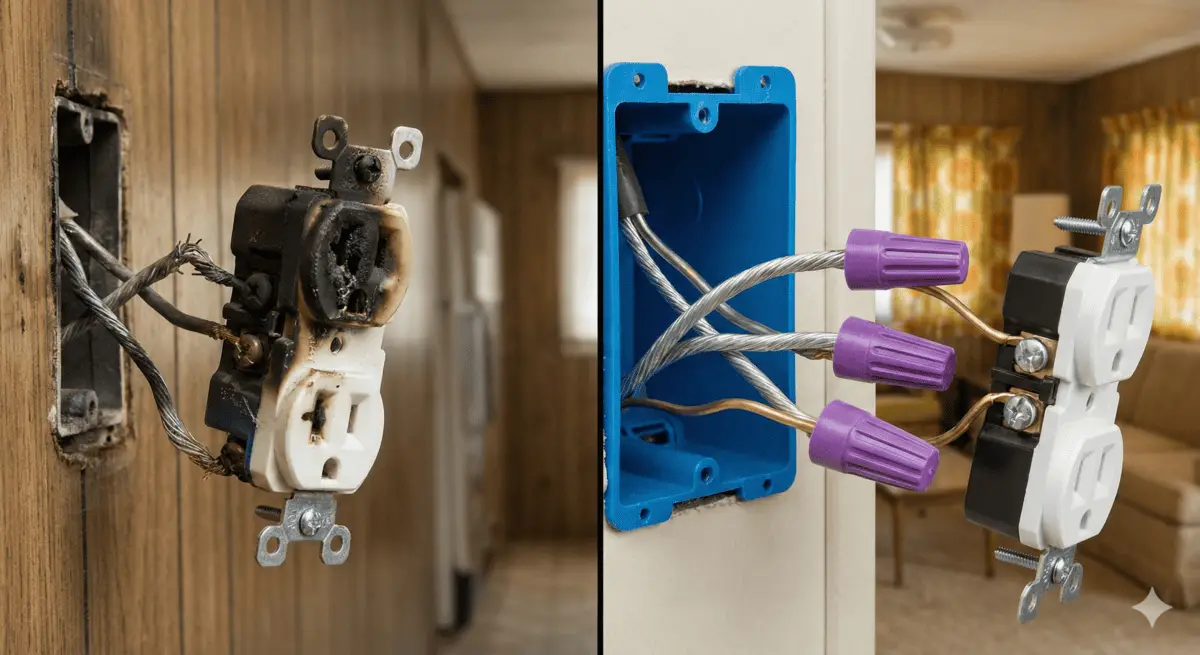

First-Person Experience: The Melted Bedroom Outlet

I remember walking through a 1972 double-wide I was looking to flip in Mesa, Arizona about ten years ago. The place was structurally sound, but it had that distinct “old house” smell. I was testing outlets in the master bedroom, and my tester showed “Open Hot” on one specific receptacle. I assumed it was just a bad outlet.

When I unscrewed the faceplate, half the outlet crumbled into dust in my hand. The plastic had been subjected to so much heat over the years that it had turned to charcoal. The aluminum wire was not even connected anymore; it was just sitting loosely in a pile of black soot inside the box. The scary part? The breaker had never tripped. The resistance was high enough to melt the plastic but not high enough to over-amp the circuit. That was the day I stopped listening to people who said, “If it ain’t broke, don’t fix it,” regarding aluminum wiring.

How to Identify Aluminum Wiring

You need to know what you are working with before you can fix it. You do not need to be an electrician to spot aluminum, but you do need to be careful.

Check the Jacket

Go to your electrical panel or an unfinished area like a water heater closet where the wiring might be exposed. Look at the plastic sheathing (the jacket) of the cable. In the 1960s and 1970s, manufacturers were required to label aluminum wiring. Look for the words “AL,” “ALUMINUM,” or “AL-CU.”

Visual Inspection of Conductors

If you cannot find markings, turn off the main breaker to the house. Verify the power is off with a non-contact voltage tester. Remove the cover plate of a switch or outlet and unscrew the device to pull it out slightly. Look at the bare wire wrapped around the screw terminals. * **Copper:** The color of a shiny new penny. * **Aluminum:** The color of a silver dime.

The “Tin-Coated Copper” Trap

Be careful not to confuse aluminum with tin-coated copper, which was also used in older mobile homes. Tin-coated copper looks silver on the outside, but if you snip the end, you will see pink copper in the center. Aluminum is silver all the way through.

The Repair Solutions: Pigtailing vs. Rewiring

If you have aluminum wiring, you have two primary paths to safety. One is expensive and destructive; the other is tedious but affordable.

Option 1: Complete Rewire (The Gold Standard)

This involves removing all old aluminum cable and replacing it with modern copper Romex. **Pros:** 100% elimination of the risk; increases home value significantly; easier to insure. **Cons:** Extremely expensive; requires opening walls, ceilings, and removing belly wrap in mobile homes.

Option 2: Pigtailing (The Industry Standard)

Pigtailing involves attaching a short piece of copper wire to the end of the aluminum wire using a special connector, then connecting that copper wire to your outlet or switch. The connection between the aluminum and the copper happens inside a specialized connector designed to prevent oxidation and loosening.

WARNING: Do Not Use Standard Wire Nuts

You cannot use standard orange or yellow wire nuts to join aluminum and copper. They will fail. The different expansion rates will cause the wire nut to fall off or melt.

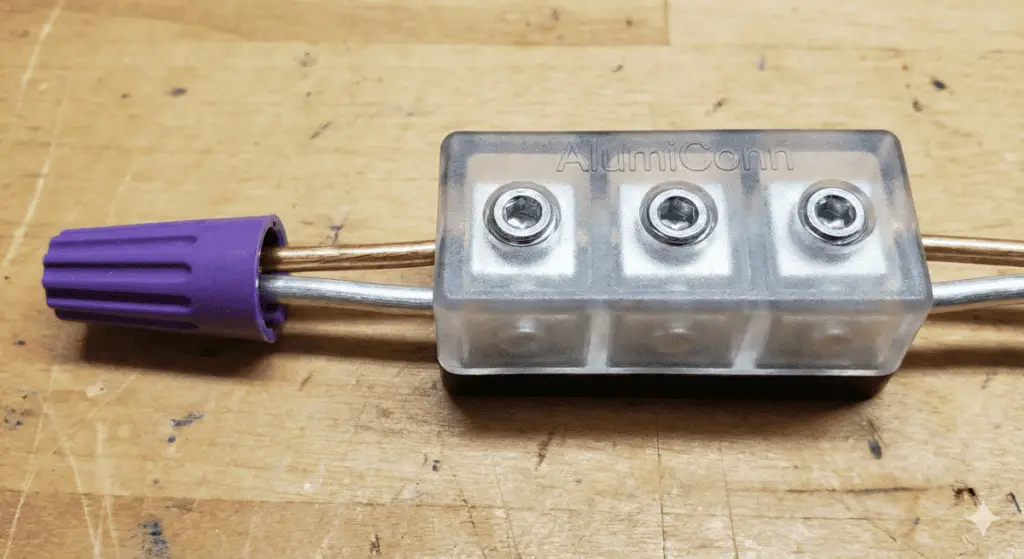

Approved Connectors

1. AlumiConn Connectors: These are small terminal blocks where the aluminum wire and copper wire are screwed into separate ports coated with antioxidant paste. They are CPSC (Consumer Product Safety Commission) approved and are the most DIY-friendly option. 2. COPALUM Crimps: This is a permanent crimp method that basically cold-welds the two wires together. It is considered the best repair but requires a licensed electrician with a specialized (and expensive) tool. You cannot rent this tool.

Cost Transparency: Fixing the Issue

The cost difference between pigtailing and rewiring is massive. Below are estimated costs for a standard 1,200 sq. ft. double-wide mobile home in 2026.

| Method | Estimated DIY Cost | Estimated Pro Cost | Notes |

|---|---|---|---|

| Complete Rewire | $1,500 – $2,500 (Materials Only) | $8,000 – $15,000 | Includes drywall repair and labor. High labor cost due to accessibility issues. |

| AlumiConn Pigtailing | $300 – $500 | $1,500 – $2,500 | Requires replacing every outlet/switch box with a deeper one to fit connectors. |

| Purple Wire Nuts | $100 – $200 | Not Recommended | AVOID. High failure rate. Many insurers do not accept these. |

Technical Deep Dive: The Issue with “Purple” Wire Nuts

You will see “Purple” wire nuts sold at big box stores labeled for Aluminum-to-Copper connections. While they are technically UL listed, many safety experts and the CPSC advise against them. The issue is that the antioxidant gel inside them can dry out, and they rely on spring tension which can fail against the strong expansion force of aluminum. In my opinion, and in the opinion of most seasoned electricians I trust, AlumiConn or COPALUM are the only acceptable fixes.

Park Models vs. Real Estate: Does it Matter?

Does the type of mobile home change the danger? No. Physics does not care if you rent the lot or own the land.

However, the financial implications differ significantly. Park Homes (Chattel): If you are in a park on a leased lot, you likely have a chattel loan or paid cash. Insurance for older homes in parks is already difficult to get. Aluminum wiring can make you uninsurable. You may be forced to use the AlumiConn method just to get a policy bind. Real Estate (Deeded Land): If your home is permanently affixed, you might be looking at FHA or VA financing for a buyer. Government-backed loans often have strict inspections. An inspector flagging aluminum wiring could kill your sale unless you can provide a certificate from a licensed electrician stating the system has been remediated.

Recommended Products for Remediation

If you decide to tackle the pigtailing route or want to verify the state of your electrical system, these are the tools I actually keep in my truck.

| Product Name | Why You Need It | Use Case | Link |

|---|---|---|---|

| King Innovation AlumiConn Connector (10-Pack) | The gold standard for DIY aluminum remediation. Uses set screws for a secure connection. | Pigtailing outlets and switches. | Check Price |

| Klein Tools Non-Contact Voltage Tester | Essential safety gear. Never touch a wire without testing it first. | Verifying power is off before work. | Check Price |

| Ideal Industries Torque Screwdriver | AlumiConn connectors require specific torque specs to be code compliant. | Tightening connector screws properly. | Check Price |

Internal Links

For more detailed information on maintaining your home’s systems, check out our guide on Mobile Home Electrical Guides. If you are doing a broader remodel, you should also read our article on Renovating Older Mobile Homes to see what other surprises might be hiding in your walls. Additionally, ensure your heating system is safe by reviewing our Mobile Home Furnace Guide.

Summary

Aluminum wiring is a serious issue, but it is a manageable one. It is not a death sentence for your mobile home investment. The danger comes from connection failure due to thermal expansion and oxidation. By identifying the wiring and methodically “pigtailing” every connection with AlumiConn connectors, you can make an aluminum-wired home just as safe as a copper-wired one. It takes time and a bit of money, but compared to the cost of a fire, it is the best investment you will ever make.

Related Questions

Can I just replace the outlets with “CO/ALR” rated outlets?

Yes, you can use outlets stamped CO/ALR (Copper/Aluminum Revised). These are designed to handle aluminum expansion. However, they are often hard to find, expensive, and limited in style (usually just standard white or ivory). They also do not solve the problem at lighting fixtures or other junction boxes, which is why pigtailing is generally preferred for a whole-house fix.

Will my insurance drop me if I have aluminum wiring?

They might. Many carriers will ask specifically about wiring type on homes built between 1965 and 1975. If you disclose it, they may require an electrical inspection or proof of remediation (like the AlumiConn fix) before binding coverage. Never lie about this on an application; it could void your claim if a fire occurs.

Why did they use aluminum in the first place?

During the mid-1960s, the price of copper skyrocketed due to geopolitical issues and supply shortages. Aluminum was cheap and abundant. The industry switched to keep housing costs down, not realizing the long-term fatigue issues that would arise at the connection points.

About the Author

Chuck O’Dell is the founder of mobilehomefriend.com. He is a real estate investor and mobile home expert with decades of experience flipping, renovating, and managing mobile homes. Chuck brings a “boots on the ground” perspective to mobile home maintenance, focusing on practical, cost-effective solutions for homeowners.

Written by Chuck O’Dell, founder of Mobile Home Friend, with decades of experience flipping and renovating vintage mobile homes.